10+ Board Feet Secrets For Accurate Lumber Costs

When it comes to lumber costs, understanding the concept of board feet is crucial for accurate calculations. Board feet is a unit of measure that represents the volume of lumber, taking into account both the thickness and the surface area of the wood. In this article, we will delve into the secrets of board feet, providing you with the knowledge to make informed decisions and avoid costly mistakes in your woodworking projects.

What are Board Feet?

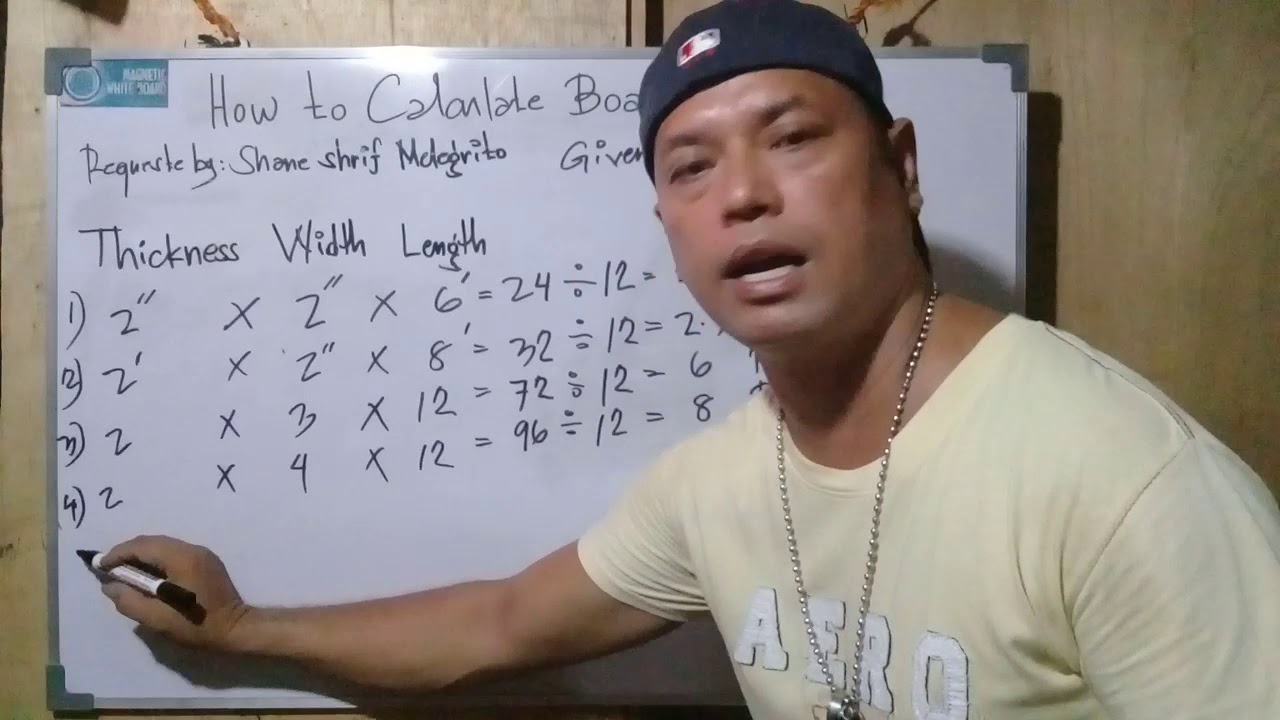

A board foot is a unit of measure that equals a piece of lumber that is 12 inches long, 12 inches wide, and 1 inch thick. This standard unit of measurement allows for the calculation of the volume of lumber, making it easier to compare prices and estimate costs. To calculate board feet, you need to multiply the length, width, and thickness of the lumber, and then divide by 12. For example, a piece of lumber that is 8 feet long, 6 inches wide, and 1 inch thick would be calculated as follows: (8 x 12) x 6 x 1 = 576 board feet.

Understanding Lumber Dimensions

When working with lumber, it’s essential to understand the different dimensions and how they affect the calculation of board feet. The dimensions of lumber are typically expressed in inches, with the thickness being the first dimension, followed by the width, and then the length. For instance, a piece of lumber that is 2 inches thick, 4 inches wide, and 8 feet long would be expressed as 2x4x8. It’s crucial to note that the actual dimensions of lumber can vary depending on the type of wood and the manufacturer, so it’s always best to check the specifications before making calculations.

| Dimension | Board Feet Calculation |

|---|---|

| 2x4x8 | (8 x 12) x 4 x 2 = 768 board feet |

| 1x6x10 | (10 x 12) x 6 x 1 = 720 board feet |

| 3x8x12 | (12 x 12) x 8 x 3 = 3456 board feet |

Factors Affecting Lumber Costs

Several factors can affect the cost of lumber, including the type of wood, the grade, and the moisture content. The type of wood can significantly impact the cost, with hardwoods like oak and maple being more expensive than softwoods like pine and spruce. The grade of the lumber can also affect the cost, with higher grades having fewer defects and imperfections. The moisture content of the lumber can also impact the cost, as lumber with high moisture content may be more prone to warping or cracking.

Lumber Grades and Their Impact on Cost

Lumber grades are a way to classify the quality of the wood, with higher grades having fewer defects and imperfections. The most common lumber grades are:

- FAS (First and Seconds): The highest grade of lumber, with few or no defects.

- #1 Common: A mid-range grade, with some defects and imperfections.

- #2 Common: A lower grade, with more defects and imperfections.

The grade of the lumber can significantly impact the cost, with higher grades being more expensive. However, it's essential to consider the specific needs of your project and choose the grade that best fits your requirements.

Calculating Lumber Costs

Calculating lumber costs involves multiplying the board feet of the lumber by the price per board foot. The price per board foot can vary depending on the type of wood, the grade, and the supplier. To get an accurate estimate of the lumber costs, it’s essential to consider the following factors:

- Type of wood: The type of wood can significantly impact the cost, with hardwoods being more expensive than softwoods.

- Grade: The grade of the lumber can affect the cost, with higher grades being more expensive.

- Moisture content: The moisture content of the lumber can impact the cost, as lumber with high moisture content may be more prone to warping or cracking.

- Supplier: The supplier can also impact the cost, with different suppliers offering varying prices for the same type and grade of lumber.

Real-World Examples

To illustrate the importance of understanding board feet and calculating lumber costs, let’s consider a few real-world examples:

Example 1: A contractor is building a deck and needs to estimate the lumber costs. The deck requires 100 board feet of 2x6 pressure-treated lumber. The supplier quotes a price of $3.50 per board foot. To calculate the total cost, the contractor multiplies the board feet by the price per board foot: 100 x $3.50 = $350.

Example 2: A homeowner is building a fence and needs to estimate the lumber costs. The fence requires 50 board feet of 1x4 cedar lumber. The supplier quotes a price of $5.00 per board foot. To calculate the total cost, the homeowner multiplies the board feet by the price per board foot: 50 x $5.00 = $250.

What is the difference between a board foot and a linear foot?

+

A board foot is a unit of measure that represents the volume of lumber, while a linear foot is a unit of measure that represents the length of lumber. To calculate the number of board feet, you need to multiply the length, width, and thickness of the lumber, and then divide by 12.

How do I calculate the board feet of a piece of lumber?

+

To calculate the board feet of a piece of lumber, you need to multiply the length, width, and thickness of the lumber, and then divide by 12. For example, a piece of lumber that is 8 feet long, 6 inches wide, and 1 inch thick would be calculated as follows: (8 x 12) x 6 x 1 = 576 board feet.

What factors affect the cost of lumber?

+

Several factors can affect the cost of lumber, including the type of wood, the grade, and the moisture content. The type of wood can significantly impact the cost, with hardwoods being more expensive than softwoods. The grade of the lumber can also affect the cost, with higher grades being more expensive. The moisture content of the lumber can also impact the cost, as lumber with high moisture content may be more prone to warping or cracking.