Confined Space: Stay Safe At Work

Confined spaces are a common feature in many workplaces, including construction sites, manufacturing facilities, and industrial plants. These areas, such as tanks, vessels, and pipes, can be hazardous if not properly managed, posing a significant risk to the safety and health of workers. According to the Occupational Safety and Health Administration (OSHA), confined space incidents result in numerous fatalities and injuries each year. In this article, we will delve into the world of confined spaces, exploring the risks associated with them, the regulations that govern their use, and the measures that can be taken to ensure a safe working environment.

Understanding Confined Spaces

A confined space is defined as an area that is large enough for a person to enter, has limited or restricted access, and is not designed for continuous human occupancy. Examples of confined spaces include storage tanks, silos, trenches, and pipe tunnels. These areas can be hazardous due to the presence of toxic gases, lack of oxygen, and explosive atmospheres. OSHA regulations require employers to identify confined spaces in the workplace and develop a plan to safely manage them.

Types of Confined Spaces

There are two main types of confined spaces: non-permit required and permit-required. Non-permit required confined spaces are those that do not pose a significant hazard to workers, such as a trench that is less than 4 feet deep. Permit-required confined spaces, on the other hand, are those that pose a significant hazard, such as a tank that contains a toxic gas. Permit-required confined spaces require a written permit and a trained attendant to ensure safe entry and exit.

The following are some common types of permit-required confined spaces:

- Tanks and vessels

- Pipes and tunnels

- Manholes and sewers

- Silos and grain elevators

- Trenches and excavations

Hazards Associated with Confined Spaces

Confined spaces can be hazardous due to the presence of various hazards, including:

Toxic gases, such as carbon monoxide and hydrogen sulfide, can be present in confined spaces, posing a significant risk to workers. These gases can be odourless and colourless, making them difficult to detect. Lack of oxygen is another hazard associated with confined spaces, which can lead to asphyxiation. Explosive atmospheres can also be present in confined spaces, posing a risk of fire and explosion.

Regulations and Standards

OSHA has established regulations and standards to ensure the safe management of confined spaces. These regulations require employers to:

- Identify confined spaces in the workplace

- Develop a plan to safely manage confined spaces

- Provide training to workers on confined space safety

- Ensure that workers use personal protective equipment (PPE) when entering confined spaces

- Monitor the atmosphere in confined spaces to detect hazardous gases

The following table outlines some of the key regulations and standards related to confined space safety:

| Regulation/Standard | Description |

|---|---|

| OSHA 29 CFR 1910.146 | Permit-required confined spaces |

| OSHA 29 CFR 1926.1200 | Hazard communication |

| OSHA 29 CFR 1910.120 | Hazardous waste operations and emergency response |

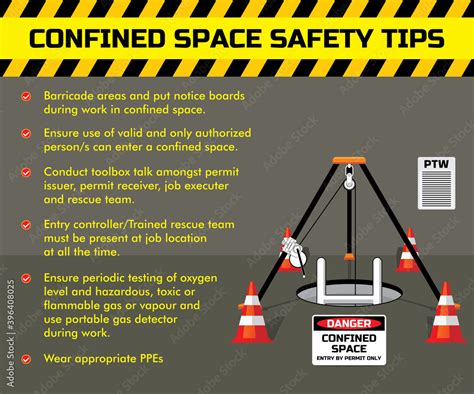

Safe Entry and Exit Procedures

Safe entry and exit procedures are critical to preventing accidents and injuries in confined spaces. The following are some key steps to ensure safe entry and exit:

Pre-entry preparation is essential to ensure that the confined space is safe to enter. This includes monitoring the atmosphere to detect hazardous gases, ensuring that the space is well-ventilated, and using PPE. Entry procedures should be established and communicated to workers, including the use of a permit system and the presence of a trained attendant. Exit procedures should also be established, including the use of a rescue plan and emergency procedures.

Rescue and Emergency Procedures

Rescue and emergency procedures are critical to responding to accidents and injuries in confined spaces. The following are some key steps to ensure a prompt and effective response:

Rescue plan should be established and communicated to workers, including the use of rescue equipment and the presence of a trained rescue team. Emergency procedures should also be established, including the use of first aid and medical treatment. Communication is essential to ensuring a prompt and effective response, including the use of two-way radios and emergency alarms.

What is a confined space?

+

A confined space is an area that is large enough for a person to enter, has limited or restricted access, and is not designed for continuous human occupancy.

What are the hazards associated with confined spaces?

+

The hazards associated with confined spaces include toxic gases, lack of oxygen, and explosive atmospheres.

What are the regulations and standards related to confined space safety?

+

The regulations and standards related to confined space safety include OSHA 29 CFR 1910.146, OSHA 29 CFR 1926.1200, and OSHA 29 CFR 1910.120.